Weighing instrument products

Packaging scale products

- Auger packing scale

- Gravity packing scale

- Belt scale

- Tons of packaging series

- Cumulative scale

- Special scale

- Valve scale

- Checkweigher

- Filling scale

- Pulse dust collector

- Feeding station

Palletizing products

Ingredient products

Pneumatic conveying products

Engineering products

Electronic control products

Non-standard products

CONTACT US

Wuxi Kefeng Automatic Control Equipment Co., Ltd.

Add: No. 11, Zhangshe Road, Hudai Industrial Park, Binhu District, Wuxi City

Business phone: +86-510-85874243

Palletizing Production Department

Contact: Chu Yushun

Tel: +86-13706193548

Stand-alone equipment department

Contact: Wu Dingguo

Tel: +86-15161509367

Weighing instrument department

Contact: Hu Yan

Tel: +86-13921158198

Ministry of Foreign Trade

Contact: Zou Dongsheng

Tel: +86-15190268138

Engineering, batching system and non-standard product department

Contact: Wu Haoqun

Tel: +8613606172914

E-mail: 8608415@qq.com

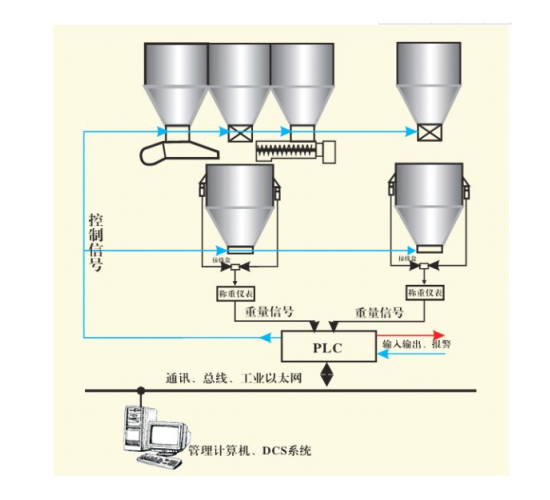

Measurement and Control System of Weighing and Batching

Release date: 2019/4/23 15:34:26 Visits: 1353

Measuring and controlling system of weighing and proportioning - automatic weighing mode of raw material proportioning control ensures the accuracy of metering control. The traditional process control system of weighing and batching system only controls the production process, and does not take part in the accounting and statistics of materials, equipment wear, overhaul and other information. This batching system has many management functions, such as equipment management, village material management and so on. According to the production situation, the system automatically counts the operating conditions of the equipment and promptly reminds the users of the overhaul, so as to improve the production efficiency and increase the service life of the equipment.

The batching system can connect seamlessly with the user''s existing MIS system or ERP system in various ways. At the same time, we can use our professional management software to make the production results and statistical information clear at a glance, so as to achieve the effect of staying at home and having a good idea. The batching system integrates computer technology, weighing technology, automatic control, communication technology into one. It has perfect control function, centralized display and operation, simple installation and maintenance, convenient data processing and easy expansion.

The software part is a visual computer operating system designed and developed to monitor and automate the batching section. It has the characteristics of simple operation, strong reliability, friendly man-machine interface and complete functions. It can be widely used in the fields of lexical materials, grain, pharmaceuticals, metallurgy, chemical industry and other industries requiring computer automatic ingredient. The level of intelligence and informatization is high: the upper computer has the function of ingredient library management; the intelligent report software provides a lot of data information for production management, such as ingredient result list, raw material consumption. Consumption list, production list, formula usage result record, etc. can be produced by time, formula, daily report, monthly report and annual report statistics and printing functions. At the same time, two user-defined report components are provided, one is to use crystal report for secondary design, the other is to seamlessly embed data into EXCEL report. In addition, the system can interact with other management systems to meet the deep data analysis requirements. The upper computer stores the cumulative measurement, ratio and start-stop time of each route in order to query. The software part of the batching system can automatically complete the batching process of the system. The computer screen shows the work flow of the batching control system in real time. The software operation is simple and the picture is realistic. At the same time, it has the following characteristics: the upper computer software sets the operation password and important parameter password modification protection, and the user realizes hierarchical management, and can arbitrarily define the rights of personnel.