Weighing instrument products

Packaging scale products

- Auger packing scale

- Gravity packing scale

- Belt scale

- Tons of packaging series

- Cumulative scale

- Special scale

- Valve scale

- Checkweigher

- Filling scale

- Pulse dust collector

- Feeding station

Palletizing products

Ingredient products

Pneumatic conveying products

Engineering products

Electronic control products

Non-standard products

CONTACT US

Wuxi Kefeng Automatic Control Equipment Co., Ltd.

Add: No. 11, Zhangshe Road, Hudai Industrial Park, Binhu District, Wuxi City

Business phone: +86-510-85874243

Palletizing Production Department

Contact: Chu Yushun

Tel: +86-13706193548

Stand-alone equipment department

Contact: Wu Dingguo

Tel: +86-15161509367

Weighing instrument department

Contact: Hu Yan

Tel: +86-13921158198

Ministry of Foreign Trade

Contact: Zou Dongsheng

Tel: +86-15190268138

Engineering, batching system and non-standard product department

Contact: Wu Haoqun

Tel: +8613606172914

E-mail: 8608415@qq.com

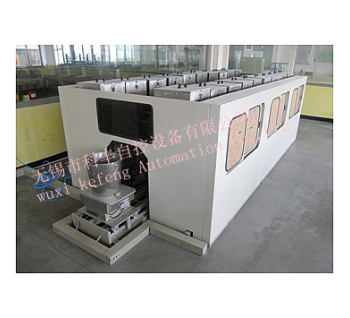

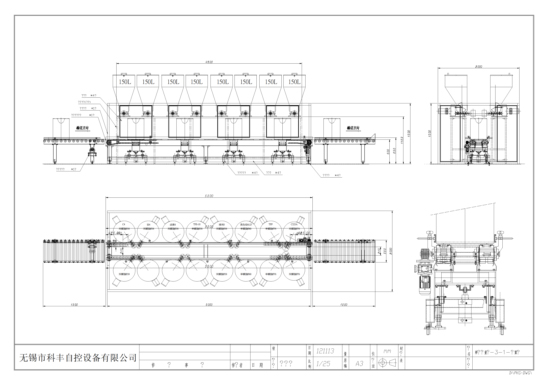

Track (mobile) batching system

Release date: 2019/4/25 10:48:35 Visits: 1044

Suitable material: Granular material, powder material, irregular material can be cross-proportioned or single characteristic material can be proportioned.

Suitable industry: Food Processing, Chemical Industry, Biomedicine, Rubber and Plastic Products, etc.

Feeding methods: auger feeding, vibration feeding, belt feeding, etc.

Equipment feature: Mobile (track) batching system can flexibly mix materials, meet the requirements of different formulations and batching metering requirements, greatly enhance the production automation, improve the accuracy and stability of batching. The equipment combines with dust collection system to ensure clean and tidy production environment.

This equipment can add designed contents: automatic bag making and bagging design in container, material warehousing design, track positioning and lengthening design and other subsequent automatic matching design.

Weighing range: single item weighs more than 5g (depending on material characteristics)

Ingredient range: more than 4 groups of materials are added randomly (depending on the working space)

Batching time: completed in a minimum of 1 minute (depending on the material formula)

Previous: micro batching and packaging