Weighing instrument products

Packaging scale products

- Auger packing scale

- Gravity packing scale

- Belt scale

- Tons of packaging series

- Cumulative scale

- Special scale

- Valve scale

- Checkweigher

- Filling scale

- Pulse dust collector

- Feeding station

Palletizing products

Ingredient products

Pneumatic conveying products

Engineering products

Electronic control products

Non-standard products

CONTACT US

Wuxi Kefeng Automatic Control Equipment Co., Ltd.

Add: No. 11, Zhangshe Road, Hudai Industrial Park, Binhu District, Wuxi City

Business phone: +86-510-85874243

Palletizing Production Department

Contact: Chu Yushun

Tel: +86-13706193548

Stand-alone equipment department

Contact: Wu Dingguo

Tel: +86-15161509367

Weighing instrument department

Contact: Hu Yan

Tel: +86-13921158198

Ministry of Foreign Trade

Contact: Zou Dongsheng

Tel: +86-15190268138

Engineering, batching system and non-standard product department

Contact: Wu Haoqun

Tel: +8613606172914

E-mail: 8608415@qq.com

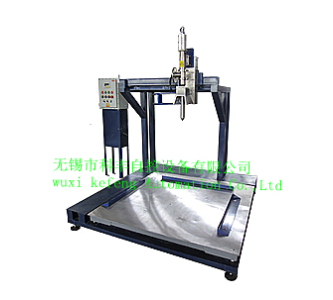

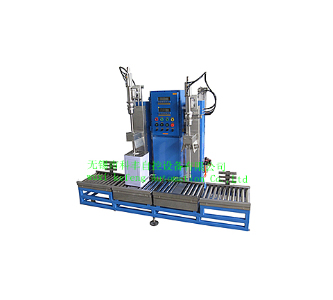

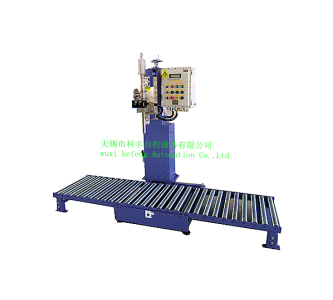

Liquid Filling Scale Series LCS-1/200QG

Release date: 2019/4/25 9:12:31 Visits: 1131

Brief instruction: The liquid filling scale has a high degree of automation, which can avoid material overflow as far as possible and prevent material itself from polluting the environment to the greatest extent, so as to provide effective labor protection for operators. Its system is stable and reliable, easy to operate, accurate weighing, and the weight data can be exported to other external equipment such as computers through instruments.

Main feature:

It can be used for accurate quantitative packaging of various containers, iron barrels or plastic barrels between 1 kg and 200 kg, and filling containers of different specifications by switching the size of sprinklers.

Adopt two-stage feeding mode to ensure filling accuracy.

Improve production safety by using explosion-proof control cabinet

Improve the Stability of Equipment by Using Intelligent Control System

Suitable industry: Food processing, grease, chemical and other industries, often need product structure surface smooth, rust-proof, anti-corrosion, even explosion-proof, such as anti-corrosion liquid filling scale, food-grade liquid filling scale and explosion-proof liquid filling scale.

Performance parameter:

Filling materials: liquid materials

Filling capacity: 1L-220L/barrel

Material Interface: 1"-2" NPT or DN25-DN50 Fast Joint Connection (Material Import Pressure < 0.4MPa)

Filling accuracy: +0.3% F.S. (Installing the correct filling system, the filling accuracy is +0.2%, and the general filling volume can reach 99.8% of the container; the accuracy depends on whether the adjustment of slow feeding is appropriate and the continuity and stability of liquid supply to the spray gun)

Filling speed: 1-12 cans/min (depending on measuring range and feeding speed, material flow rate in pipeline should be guaranteed to reach 90L/min)

Measuring method: liquid two-stage feeding control

Barrel Specification: Small Side Opening/Full Opening

Relative humidity: ≤90RH%(no condensation)

Suitable temperature range: ~10℃~45℃;

Control power supply: AC220V(﹣15%/+10%)/50HZ(±10%)

Power supply: AC380V(﹣15%/+10%)/50HZ(±10%)

Power: about 1.1~5.5KW(Depending on the size of the range)

Pressure: 0.4MPa~0.6MPa

Air consumption: 0.3m3/h

This equipment can be used in connection with the following equipment:

Automatic empty tank handling equipment

Automatic positioning capping equipment

Automatic weight-checking and eliminating equipment

Automatic labeling and spraying equipment

Palletizing and conveying equipment

Liquid Filling Scale Series LCS-1/200QG

Order Requirements for Packing Scales

Previous: Pulse dust collector