Weighing instrument products

Packaging scale products

- Auger packing scale

- Gravity packing scale

- Belt scale

- Tons of packaging series

- Cumulative scale

- Special scale

- Valve scale

- Checkweigher

- Filling scale

- Pulse dust collector

- Feeding station

Palletizing products

Ingredient products

Pneumatic conveying products

Engineering products

Electronic control products

Non-standard products

CONTACT US

Wuxi Kefeng Automatic Control Equipment Co., Ltd.

Add: No. 11, Zhangshe Road, Hudai Industrial Park, Binhu District, Wuxi City

Business phone: +86-510-85874243

Palletizing Production Department

Contact: Chu Yushun

Tel: +86-13706193548

Stand-alone equipment department

Contact: Wu Dingguo

Tel: +86-15161509367

Weighing instrument department

Contact: Hu Yan

Tel: +86-13921158198

Ministry of Foreign Trade

Contact: Zou Dongsheng

Tel: +86-15190268138

Engineering, batching system and non-standard product department

Contact: Wu Haoqun

Tel: +8613606172914

E-mail: 8608415@qq.com

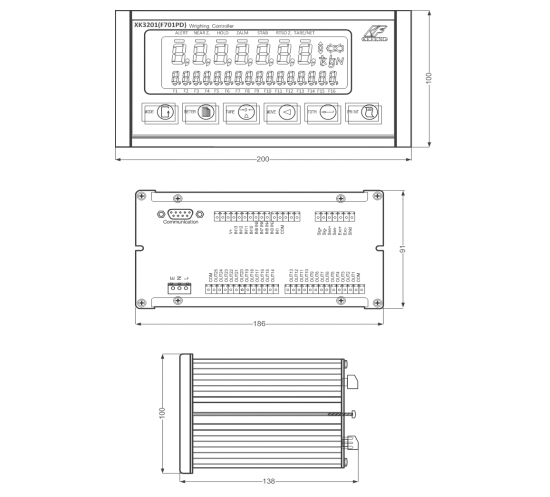

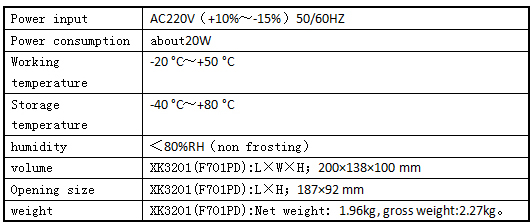

XK3201(F701P/PD)

Release date: 2019/4/23 14:24:42 Visits: 1476

Six multi-function keys can realize all the "man-machine interface" work, such as setting, viewing and modifying, and have good operation performance. Even the first use of our company''s display can be easily set values and other input operations.

high performance

Because of using the recognized excellent preamplifier (made in USA) as the input amplifier of the weighing sensor, the indicator has supergroup zero stability and gain stability.

high speed

With 100/second high-speed A/D conversion processing, the instantaneous weight change can also be quickly responded to, thus greatly improving the performance of the metering indicator.

high precision

The display accuracy of 1/10,000 can be guaranteed in all input ranges.

Settable filtering function

It can play an adjustable multi-stage digital filtering function for stray interference wave produced by electromagnetic and mechanical vibration. According to different purposes, the filter can be adjusted at will to control the influence caused by the vibration of mechanical system, so as to improve and ensure high speed and accurate measurement.

Simple calibration

Digital Span is adopted to simplify the initial operation process.

batching function

The prescription setting values of 10 different raw materials can be set and recorded. Each prescription can control the fast and slow feeding of 8 materials. At the same time, XK3201 (F701P/PD) also controls the buffer bin and mixer of the batching system. It is convenient to set the discharge time of buffer bin, mixing time and mixer discharge time. Various set values, correction values, cumulative values and other data are stored in FRAM (non-volatile ferroelectric memory). Even in the case of sudden power outage, the data will not be lost. At the same time, the current batching state in the batching process can be remembered, so that the batching breakpoint can be continued after the power is restarted.

Multifunctional sequential control

In addition to the batching function, the controller can also control many forms of control sequence after updating the program, such as: weight reduction scale, weight loss scale, weighing scale and so on.

Recovery of factory parameters

All settings of the display can be set (scale value is not restored).

Data calibration

The digital calibration function can be accomplished by using the front panel buttons.

The digital calibration function can be accomplished by using the front panel buttons.

The voltage of the power supply can be selected in the range of 187-242V.

Previous: XK3201(F701B)

Next: XK3201(F701B)